History of 3D printers and how they work

Now the familiar word "printer" is translated from English as a printing device. Now it is rare to find a person who has never seen a regular printer with which you can get any text or graphic paper document.

The history of the appearance of the printer in the current sense began in the last century – the first black-and-white printer appeared back in 1953, and in 1976 the first color inkjet printer from IBM appeared. Today, a variety of printers can be found not only in offices and organizations, but also in schools and in almost every home. After all, the modern process of work and learning has become unthinkable without this device.

However, in recent years, a completely new device has appeared that can not only print any image on a piece of paper. We are talking about the invention of a 3d printer, with which you can already create three-dimensional parts, products or models.

History of the 3D printer

The history of 3d printers, surprisingly, is quite long, and scientists from many countries of the world worked on the creation of this device, gradually contributing to the development of three-dimensional technologies.

- In 1986, the American Chuck Hull invented the principle of three-dimensional printing, which was used in a stereolithography setup.

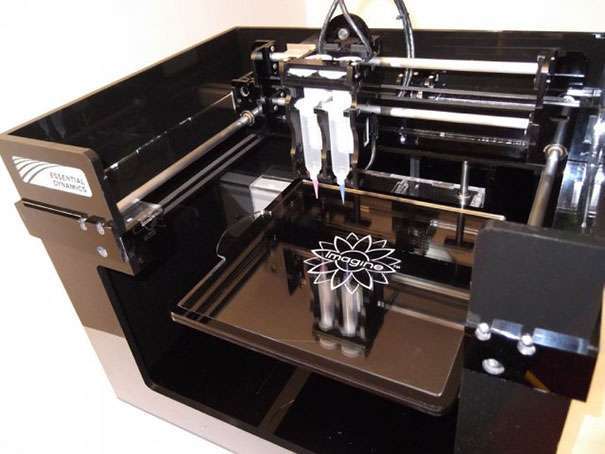

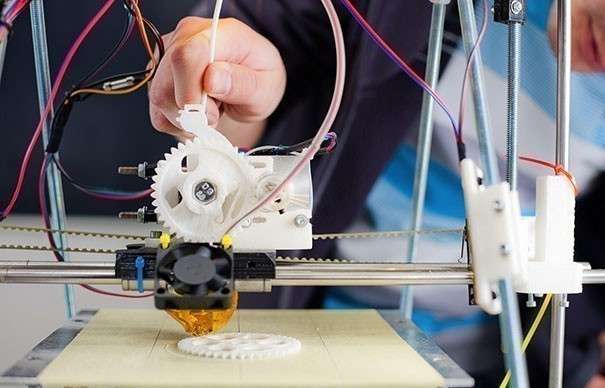

- In 1988, another American, Scott Crump, found a completely different approach to the implementation of three-dimensional printing – molding through the decomposition of a fusible material (FDM). Today, all three-dimensional printers that can make products on a limited scale work on this principle.

- Although work on the creation of three-dimensional printers began in the eighties of the last century, the term "three-dimensional printing" itself appeared only in 1995 in the depths of the Massachusetts Institute of Technology. And the very next year, 3D Systems called its first model the Actua 2100 a 3D printer. A 3D printer has such a history of creation, in short.

The first three-dimensional printing models were very slow, and an attempt to increase the speed of their work invariably led to errors in the products. Three-dimensional printers with a sufficiently high quality of products appeared only in 2005. In 2008, the Reprap model appeared, half capable of recreating itself, since it could make half of its parts.

3d printing technologies

Three-dimensional printing can use different technologies and consumables, but in any case, it works through the sequential build-up of layers of a three-dimensional object. Various technologies can be used to create layers.

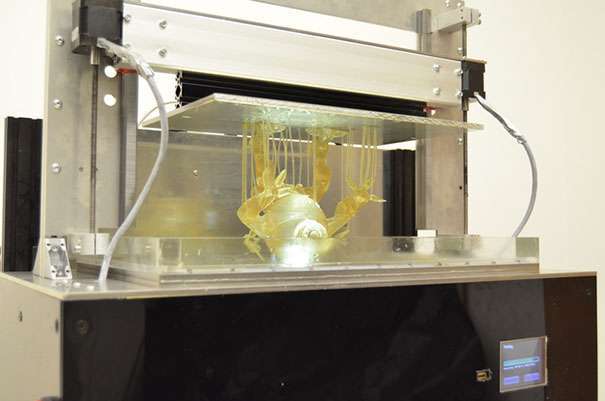

Laser stereolithography, in which an ultraviolet laser illuminates the surface of a liquid photopolymer point by point. In another variant, illumination is performed with an ultraviolet lamp through a photomask changing with a new layer. The liquid polymer then hardens, becoming a fairly durable plastic.

- Laser fusion is used for layers of plastic or metal powders.

- Lamination – here the layering of the material is also carried out, all layers are glued together, and sections are cut out with a laser in each layer, forming a section of the future object.

- The jet technology provides for the solidification of the cooling material: the dispensing nozzle throws heated drops of thermoplastic onto the cooled base platform. There they instantly solidify, sticking together with neighboring ones, and form a layer of the part being made.

- Bonding a powdered material is somewhat similar to sintering a powder with a laser beam, but the powder here can be ground cellulose, which does not melt, so a liquid adhesive or solvent is used to glue it, which is fed from a miniature nozzle. With this method, you can give the part the desired color if you use multi-colored dyes. There are even models of three-dimensional printers that use heads from conventional inkjet printers.

- Thick ceramic mixtures can also be used as self-curing materials. Such materials are in demand for 3D printing of large architectural models.

- The latest achievement is bioprinters. So far, these are only experimental facilities that form the three-dimensional structure of an organ for transplantation. They use solutions containing living cells. Cells then grow, divide, and specialize to form the final shape of the organ.

Raw materials for 3D printers

All volumetric printers until 2008 could use only one type of plastic – ABC, which was the best "consumable" for three-dimensional printing. Object Geometries Ltd released the first model "Connex500", which could use several types of materials at the same time. Now the list of such materials has exceeded one hundred. Among them are the following:

- cellulose;

- hydrogel;

- concrete;

- acrylic;

- water;

- gypsum;

- nylon;

- metal powder;

- polylactide;

- polycaprolactone;

- low-pressure polyethylene;

- polypropylene;

- chocolate.

The peculiarity of the work of three-dimensional printers is that all the resulting objects can only be solid-state, since they are applied layer by layer. On a conventional printer, you can only make a paper document, and on a three-dimensional printer you can “print" a children’s toy, fabric suitable for sewing, plastic utensils, even implants for medical purposes or a car. Volumetric printers of the new generation have very great opportunities.

Video about the history of 3d printers

The amazing possibilities of 3D printers

Three-dimensional printers are gradually becoming useful and necessary devices in our lives, and their areas of application are expanding more and more. So, small three-dimensional printers are capable of making household items, such as dishes, toys, jewelry, and even furniture.

- In 2010, Canadian Jim Kor demonstrated a passenger car whose body was completely made on a three-dimensional printer, which took 2,500 hours of work. The creators of the unique car even got together to get from New York to San Francisco in a couple of days, using only 38 liters of biofuel.

- In 2010, Organovo Inc. announced that it had created a three-dimensional technology for the manufacture of artificial blood vessels. Previously, the use of this technology for medical purposes was out of the question. At present, many prosthetic surgeries have already been performed in the world, where implants made using this technology have been implanted in patients – skull and nose bones, dental, hand bones, etc.

- Much more modest is the demonstration in 2011 by the British of a printer that could make any figure out of chocolate. Since chocolate is able to harden quite quickly when cooled, the printer prints on such raw materials quite quickly. Such printers are a real find for restaurants and pastry shops.

In the same year, the first aircraft was made on a three-dimensional printer by the efforts of British engineers from the University of Southampton. They admitted that the greatest difficulties were not in the printing process, but in the design. The manufactured model was able to fly at a decent speed.

Scientists from Oxford have proposed a printer that can reproduce material that partially has the properties of living tissue. Italian roboticist Enrico Dini taught a 3D printer to make models of two-story buildings that have rooms with partitions, pipes and stairs. All this is done from an inorganic compound and sand. The resulting material has a strength close to that of reinforced concrete.

Engineering thought did not stop there, since a proposal was made to use this technology in the construction of lunar research bases. It was decided to deliver a three-dimensional printer to the ISS, where astronauts can quickly produce the parts they need, without waiting for them to be delivered from Earth.

Now 3d printers, which started out as bulky and very expensive, are getting smaller and cheaper. In 2011, the Austrians demonstrated the lightest, smallest and cheapest volumetric printer to operate. Additive photopolymerization technology was used here, working with a photosensitive resin.

Video about the possibilities of a 3d printer

It used to be thought that 3D monitors were an unattainable luxury for a simple layman, but today even poor citizens can buy them. It is the same with 3D printers – they have already ceased to be machines from science fiction books, but are more and more confidently entering reality, bringing more and more benefits. Their prospects are very good.